AI Platform

for Combustion

Get A Free Demo

WHY USE PYRETEK?

Lower Energy Consumption

Higher Production

Safety Improvement

Lower Downtime

Lower Emission

TYPES OF DATA ANALYSED

Operational Data

Furnace Temperature, Furnace Pressure, Burner Power

Energy Consumption Data

Burner Power, Fuel/O2/Air Flowrates.

Safety And Reliability Data

Shutoff valves, Pressure and Temperature switches, UV sensors, Pressure and Temperature sensors

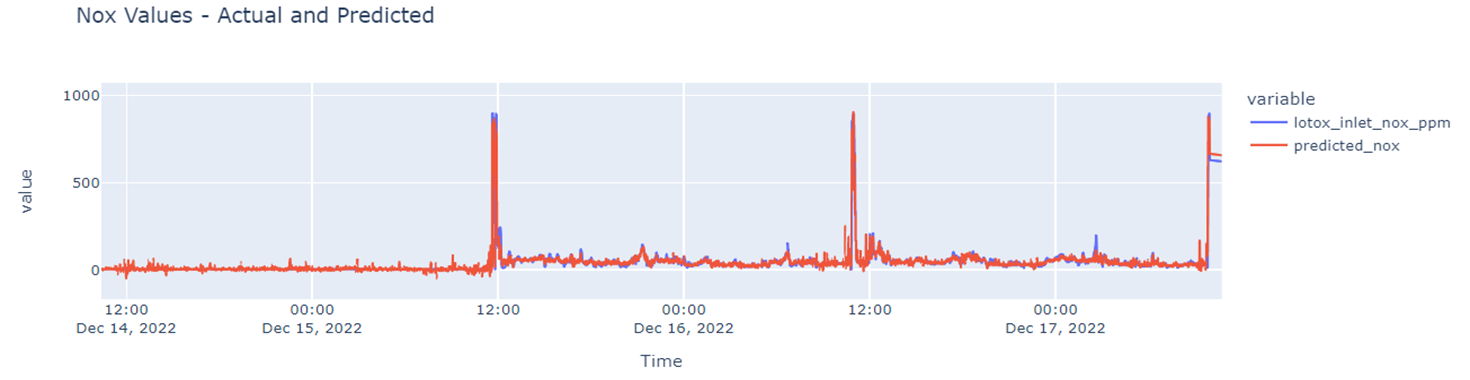

Emission Data

NOx/O2/CO sensors

Lower Energy Consumption

Higher Production

Safety Improvement

Lower Downtime

Lower Emission

HOW DOES IT WORK?

Lower Energy Consumption

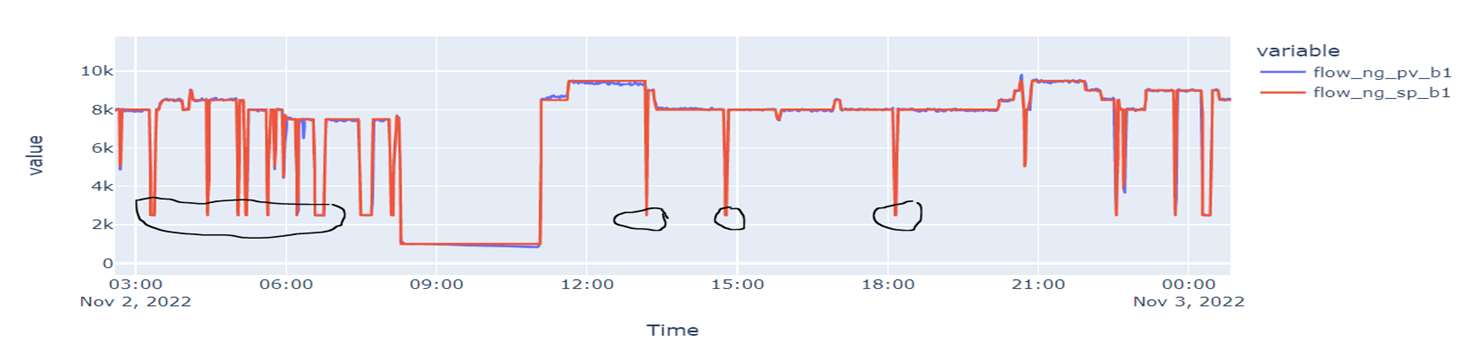

Ensuring Safety Device Reliability And Detecting Operational Or Maintenance Errors For Secure, Seamless Operations

Higher Production

Driving CO₂ And NOx Reduction Through Optimized Energy And Oxygen Consumption Efficient Burner Management, And Minimized Unplanned Shutdowns.

Safety Improvement

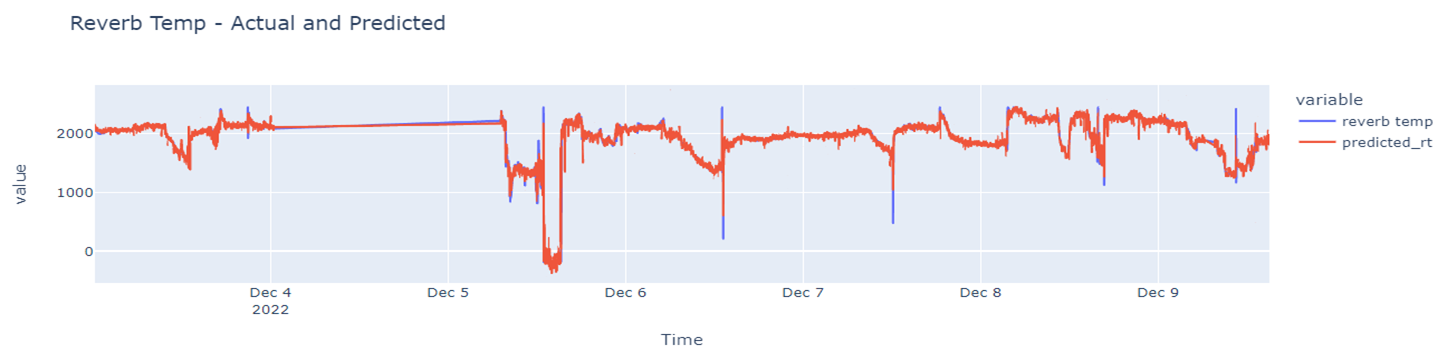

Proactively Predicting Device Failures And Ensuring Compliance With Emission Permits For Sustainable Operations

Lower Downtime

Maximizing Metal Yield, Minimising Downtime, And Eliminating Bottlenecks For Streamlined, High-Efficiency Production

Lower Emission

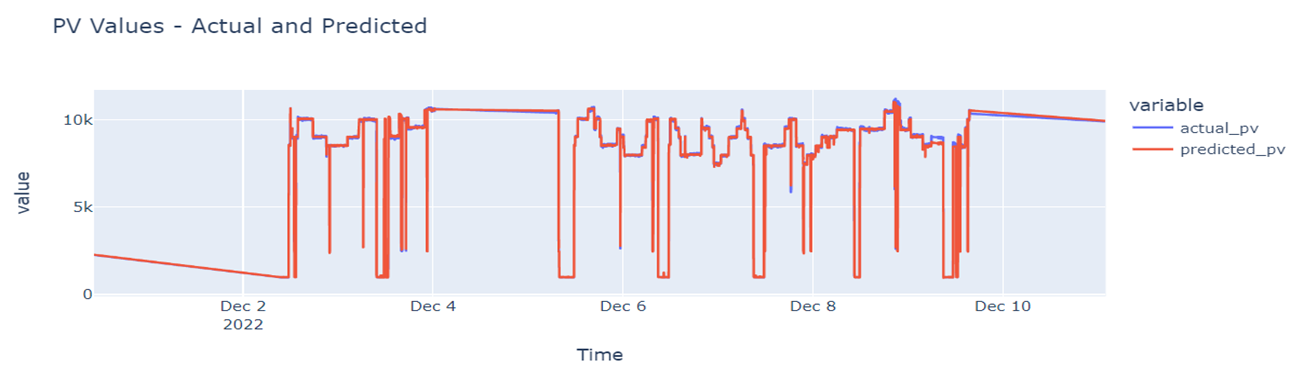

Enhancing Precision And Stability in Flow Control, Metering, And Pressure Measurement For Optimal Performance

THEY TRUST US

Use Cases

Explore how Pyretek optimizes combustion processes across various industrial applications.

FREQUENTLY ASKED QUESTIONS

Have a question? We are here to help